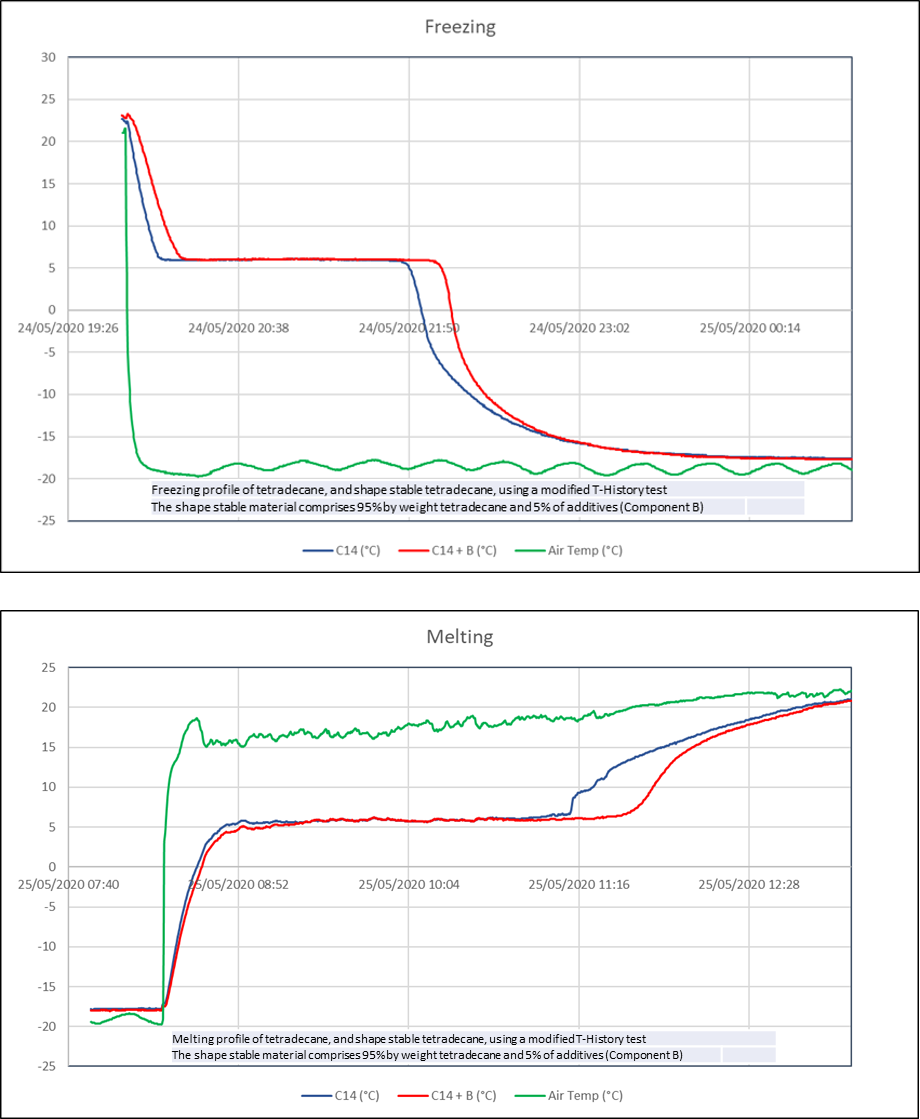

The melting and freezing results shown were obtained using a modified version of the T-History test. Whilst this lacked the sophistication of three layer calorimetry or DSC, it nevertheless enabled comparative results to be obtained. Pure tetradecane was compared to a sample comprising 95% tetradecane and 5% of an additive package we call “Component B”. There was no apparent difference between the samples on freezing but, potentially, a slight improvement in the performance of the shape stable material on melting. Hence, the novel shape stable material not only provided equivalent performance to neat tetradecane, it did so whilst protecting against leaks and spoilage of the payload during the cold chain cycle.